Printed Circuit Board (PCB) Repairing Services

In today’s technology-driven world, Printed Circuit Boards (PCBs) are the backbone of electronic devices, from household gadgets to industrial machinery. As these devices become more complex, the demand for skilled PCB repair services has surged. Whether it’s a smartphone, a computer, or an industrial control system, efficient PCB repair can save time and cost by extending the lifespan of electronic equipment. This blog explores the intricacies of PCB repair services, highlighting the process, common issues, benefits, and why professional services are crucial.

The Importance of PCB Repair Services

PCBs are intricate assemblies of electronic components interconnected by conductive pathways. They are essential for the functionality of electronic devices, and any failure can lead to significant disruptions. Professional PCB repair services are essential for:

- Cost-Effectiveness: Repairing a PCB is often more economical than replacing the entire board or device, especially in high-end electronics and industrial machinery.

- Time Efficiency: Quick repair services minimize downtime, ensuring that personal and business operations continue smoothly.

- Sustainability: Repairing and reusing PCBs contribute to reducing electronic waste, promoting environmental sustainability.

- Expertise and Precision: Professional repair services employ skilled technicians who can diagnose and fix issues accurately, ensuring the longevity and reliability of the device.

Common PCB Issues

PCBs can encounter a range of issues, including:

- Component Failure: Over time, components like capacitors, resistors, and integrated circuits can fail due to age, heat, or electrical surges.

- Solder Joint Problems: Poor or cracked solder joints can lead to intermittent connections or complete failure.

- Trace Damage: Physical damage or corrosion can break the conductive pathways on a PCB, disrupting the flow of electricity.

- Power Supply Issues: Inconsistent or faulty power supplies can cause voltage fluctuations, damaging the PCB and its components.

- Thermal Stress: Overheating can cause components to fail and can warp the PCB itself, leading to operational issues.

The PCB Repair Process

Professional PCB repair involves several steps to ensure thorough and effective restoration:

-

Initial Assessment:

- Visual Inspection: Identifying visible damage such as burnt components, cracked solder joints, or corroded traces.

- Diagnostic Testing: Using specialized tools to test components and trace paths for faults.

-

Component Replacement:

- Desoldering: Carefully removing faulty components without damaging the PCB.

- Sourcing Parts: Procuring high-quality replacement components to ensure reliable repairs.

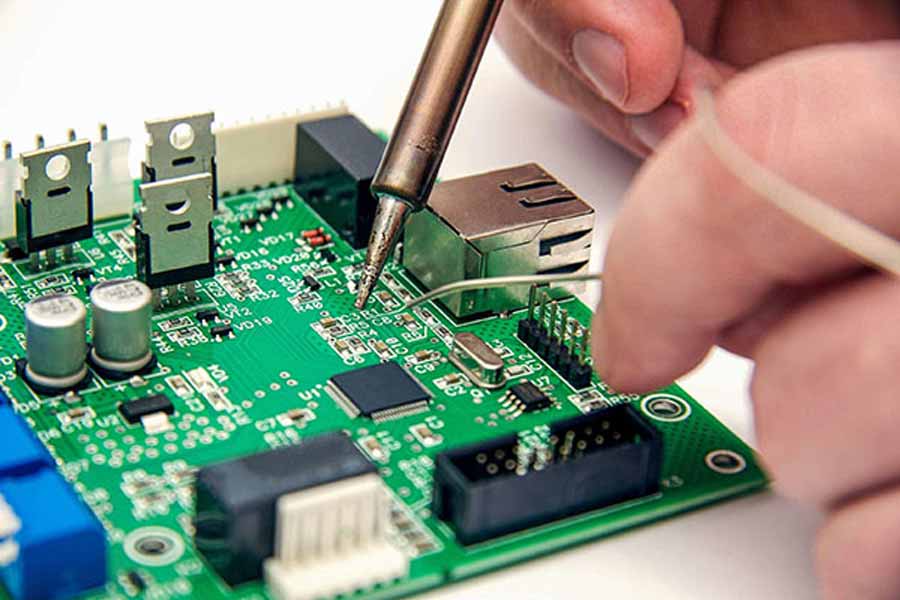

- Soldering: Skillfully attaching new components with precise soldering techniques.

-

Trace Repair:

- Cleaning: Removing any corrosion or debris from damaged areas.

- Reconstructing Traces: Using conductive ink or wire to restore broken pathways.

-

Testing and Quality Control:

- Functionality Testing: Verifying that the PCB operates correctly after repairs.

- Stress Testing: Ensuring the board can withstand typical operational conditions without failure.

- Final Inspection: Conducting a thorough review to confirm the integrity and reliability of the repair.

-

Documentation and Reporting:

- Detailed Report: Providing a comprehensive report on the repairs performed, including diagnostic findings, components replaced, and testing results.

- Warranty: Offering a warranty on the repair work to guarantee quality and build customer trust.

Benefits of Professional PCB Repair Services

Choosing a professional PCB repair service offers several advantages:

-

Expert Technicians:

- Trained and experienced technicians ensure accurate diagnostics and repairs, enhancing the longevity of your electronic devices.

-

Advanced Equipment:

- Professional services utilize state-of-the-art diagnostic and repair tools, ensuring precision and quality in every repair.

-

Quality Assurance:

- Rigorous testing and quality control processes ensure that repaired PCBs meet or exceed original performance standards.

-

Customer Support:

- Comprehensive support, including detailed repair reports and post-repair assistance, ensures a smooth and satisfactory experience.

Conclusion

In an era where electronic devices are integral to daily life and business operations, reliable PCB repair services are indispensable. They offer a cost-effective, time-efficient, and environmentally friendly solution to electronic device failures. Professional PCB repair services, with their expertise, advanced equipment, and commitment to quality, ensure that your devices remain functional and efficient. By choosing a reputable PCB repair service, you can extend the life of your electronics, minimize downtime, and contribute to a more sustainable future. Invest in professional PCB repair services and experience the difference in performance and reliability.

Comments (0)